To celebrate National Women In Engineering Day on June 23rd 2016, New Technology CADCAM is focusing on the outstanding achievements of SOLIDWORKS customers who are accomplishing innovations day-to-day in the UK engineering and design industry.

Rachel Nagy, project manager, Owen Mumford, went into engineering to make a difference. Even as a child, she was obsessed with the tiny things in life that could make a big difference; everyday medical products from syringes to pump sprays that would have a massive impact on people’s lives and health. It’s a passion for designing and working out how to get millions of these ‘magical’ products into the manufacturing process and out to the world, that made her carve a successful and rewarding career in engineering. An R&D project manager for global medical device manufacturers, Owen Mumford, Rachel tells how she is making a difference.

Q. How did you first become interested in engineering?

I suppose it’s in my genes. As a child I always loved the toys in Kinder Eggs, but only the ones that had to be assembled. Anything that came as a one-piece toy would be an insult to my intellect!

But mostly I remember wandering through the supermarkets back home in Hungary and being fascinated by all these clever products that were making people’s lives better, especially in the healthcare section.

The idea that millions of these tiny identical products—like toothbrushes, dental floss, syringes, make-up and the clever packaging of medicines—were making a big difference in people’s lives was an exciting concept to me. Who were the superstars behind them? Who was making the decisions on shapes, sizes, colour, scent and even the feel of a new product? I wanted to understand how you could make millions of the same shape.

Q. What did you study?

I completed a five-year Product Design Engineering programme at the Budapest University of Technology and Economics. It was a rigorous Mechanical Engineering based course. The other pillars of the course were: Human Factors Engineering-Ergonomics and Marketing and Management. From day one, next to our theoretical studies, we were working in teams to develop a brand new product every term, which we had to present to a board of professors and industry experts. We had to meet rock solid deadlines with full technical documentation, prototypes and a presentation. It was overwhelming at first, then gradually it became a fantastic game that shaped my whole work ethos.

After completing the course I realised I still hadn’t taken any of my designs to all the way to mass production. I wanted to learn more about mass production, manufacturing simulation and design for manufacturing to shorten the time to get an idea to market. I took a Masters in Computer Aided Engineering with Manufacturing at the University of the West of Scotland. There I had the opportunity to complete an amazing reverse engineering project, use innovative manufacturing and simulation technologies and design my own injection-moulding tool and mould the parts of my product with it. I used virtual prototyping techniques, reverse engineering, 3D printing and soft tooling technologies to reduce my design time to market.

Q. What have you made?

I joined Owen Mumford as a New Product Introduction (NPI) Engineer. It was the ultimate dream for me because Owen Mumford does more than design, it also mass manufacture small plastic components—such as Autopens for injecting, blood sampling devices for diabetics and eye care solutions to make administering drops—all of which have a global impact on human welfare.

My proudest project in my engineering role was to design, build and validate an assembly line for a new autoinjector that helps many people, especially the elderly, to self-inject and self-manage medication.

One of the most satisfying moments was meeting a very tight deadline to develop an automated gluing machine that could reduce the amount of time it took the glue to cure on these autoinjectors. I was working round the clock with some very talented engineers to overcome technical challenges. It was tough but we did it and ended up literally pulling the machine in with our own hands on the planned completion date. It was a fantastic day.

Q. What does your role at Owen Mumford involve?

For the last 18 months I’ve been working at Owen Mumford as an R&D project manager. It’s a role I love, working with bright engineers to see new products through the design and industrialisation cycle, on time and on budget.

My background in engineering helps me connect and communicate with the team, I’m more aware of the technical risks and also the opportunities, which we can exploit to deliver successful projects.

Q. How do you use SOLIDWORKS?

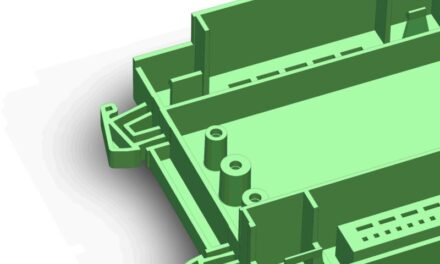

At work we use Solidworks for a variety of tasks in the product design process. Everything from the initial concept stage, to creating 3D models that we can send directly to the toolmaker. SOLIDWORKS has a great rendering module that lets us quickly render realistic images from the model that we can send direct to the customer.

At home, I use SOLIDWORKS for fun! SOLIDWORKS has a very intuitive user interface so when an idea storm hits me I can get my ideas into SOLIDWORKS immediately. I save my ideas into models and then print the STL files on my 3D printer.

Q. Women still only make up 8% of the UK engineering workforce. What advice would you give to women thinking of going into design and engineering?

I dream of a world where we all have the chance to achieve our full potential. Gender equality is part of this. I know that it is beyond my lifetime and I take ownership of my role in the change. We need more female role models in engineering to inspire and show young girls that they can chose careers outside traditional female roles and create and lead diverse teams of engineers that can create value together.

Difference is power: Having diversity in a team is a great opportunity. We need to harvest the power of our differences and create functioning and fulfilling, diverse teams. My advice to any women who are thinking of going into design and engineering is—if you are going to be one, be a good one, and be proud of it, knowing that you are part of something larger than your life.

Rachel uses SOLIDWORKS provided by New Technology CADCAM, the designers’ and engineers’ choice for technical software, professional services and advice. For further information or to book a demo with New Technology CADCAM, call 0800 018 6957 or visit www.thenewtechnologygroup.com