After twenty years, HepcoMotion’s flagship GV3 range is continuing to lead the way, serving a diverse range of linear and automation applications. With the introduction of new components to the range, and a new product category, Hepco has produced a series of six animations highlighting the major benefits of V Guide technology against ball rail systems. A useful resource for design engineers, the technical animations showcase the unique features and benefits of GV3 and highlight how V guide systems can save designers both time and money.

After twenty years, HepcoMotion’s flagship GV3 range is continuing to lead the way, serving a diverse range of linear and automation applications. With the introduction of new components to the range, and a new product category, Hepco has produced a series of six animations highlighting the major benefits of V Guide technology against ball rail systems. A useful resource for design engineers, the technical animations showcase the unique features and benefits of GV3 and highlight how V guide systems can save designers both time and money.

Harsh environment

Specifying a linear motion product for a harsh environment can be a challenge. The ability to cope with factors such as extreme temperatures, dust, dirt or chemical exposure is a combination only the toughest systems can survive. Hepco’s V guide systems have a unique wiping action that tends to expel debris – making it perform particularly well in harsh environments. The animation visually shows how the outer diameter of the bearing travels at a faster speed than the inner diameter. The difference in speed causes particles nearer the centre to move outwards to the periphery, and to be expelled. Due to the geometry of the slide and bearing interface, debris is expelled to the outer diameter of the bearing in a spiral motion, away from the running surface. This complex explanation is effortlessly explained in a graphic way through the visual animation in a clear and engaging way.

https://www.hepcomotion.com/videos/animation-gv3-harsh-environment/

https://www.youtube.com/embed/ZniYMRqJZZk

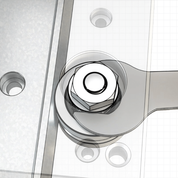

Eccentric Adjustment

Eccentric Adjustment

This animation focuses on a key benefit of V technology; the ability to adjust the system if wear occurs after a long service life. The animation shows how the eccentric bearings on the GV3 carriage can be adjusted to remove any play, while the ball rail has to be removed and replaced with a new one. The ability to adjust the bearings often makes the cost of GV3 lower over the total machine life. Moreover, when the V bearings reach the end of their calculated life, they can be replaced individually, and not as an entire set, so perfectly good components do not have to be discarded unnecessarily.

https://www.hepcomotion.com/videos/animation-gv3-eccentric-adjustment/

https://www.youtube.com/embed/ZDfYiHJXFDc

Compliance

Linear guides are mounted to both uneven surfaces and machined surfaces, making compliance a key consideration for design engineers. Ball rail systems for example, cannot tolerate any deviation in mounting flatness, and require surfaces to be machined prior to installation. Hepco’s compliance animation shows the ability of GV3 to cope with variances in mounting surfaces and mounting guides out of parallel.

Linear guides are mounted to both uneven surfaces and machined surfaces, making compliance a key consideration for design engineers. Ball rail systems for example, cannot tolerate any deviation in mounting flatness, and require surfaces to be machined prior to installation. Hepco’s compliance animation shows the ability of GV3 to cope with variances in mounting surfaces and mounting guides out of parallel.

Using animated images of a GV3 slide and a ball rail mounted to an uneven surface, the animation shows a close up of the GV3’s twin bearing parting slightly to cope with the errors, while the ball rail begins to stop. The internal structure of the runner block is shown with the balls ceasing up, highlighting how failure to machine mounting surfaces will result in poor quality movement, binding of the runner block and premature failure of the system.

The unique design of Hepco’s GV3 V bearing allows it to perform when mounted to a surface that is uneven or has not been machined. GV3 twin bearings are constructed from two pieces, allowing a small amount of compensation for deviation in mounting surface flatness.

Any engineer will know that when mounting parallel linear guide systems across a wide span and over a long distance, setting them up accurately is a very difficult and time consuming process. The compliance animation shows the Hepco system running when two V guides are mounted out of parallel and how the twin bearings split apart to compensate. This incredibly beneficial feature allows parallelism to deviate by +/-0.05mm and reduces the set up time needed to accurately assemble systems. Floating bearings can be specified to overcome misalignment even further, and can compensate up to +/- 1.25mm, but with the inclusion of Hepco’s Flat Track and Roller system a total deviation of +/- 2.5mm is possible.

https://www.hepcomotion.com/videos/animation-gv3-compliance/

https://www.youtube.com/embed/kF5KD4KPzMU

Lubrication

Supplying a constant source of lubrication is a key consideration for any design engineer; Hepco has therefore created an animation dedicated to showing how this can be managed using standard Hepco options. This animation shows the different possibilities of lubrication delivery available with Hepco’s V guides, such as the automated bleed lubrication system which delivers lubricant directly to the contact surface between the slide and the V bearings. The animation shows a cross section of the slide rail with a bleed lubrication hole from the underside, joining with a perpendicular channel which is routed through the V face.

Supplying a constant source of lubrication is a key consideration for any design engineer; Hepco has therefore created an animation dedicated to showing how this can be managed using standard Hepco options. This animation shows the different possibilities of lubrication delivery available with Hepco’s V guides, such as the automated bleed lubrication system which delivers lubricant directly to the contact surface between the slide and the V bearings. The animation shows a cross section of the slide rail with a bleed lubrication hole from the underside, joining with a perpendicular channel which is routed through the V face.

Here, lubricant is pumped up and out at right angles directly to the running face of the bearings and slide – exactly where it is needed. The lubrication source supplies grease constantly, and being remotely located, the system does not need to be stopped at regular intervals for re-lubrication, reducing downtime and increasing machine efficiency.

Ball rail re-lubrication intervals are far shorter than V guide systems, with frequent maintenance and downtime required to keep them running. The animation shows how ball rails will eventually purge any lubrication from within the block, leading to catastrophic failure if not re-lubricated regularly. Re-lubrication intervals are far longer for the GV3 system, and it requires less lubricant to work effectively.

The animation also showcases the ability of GV3 to run completely dry – a requirement for some food, medical and scientific applications. A cross section of the V bearing shows the internal ball bearings continuing to work perfectly well, moving the GV3 up and down the guide without lubrication, and problem free.

https://www.hepcomotion.com/videos/animation-gv3-lubrication-and-run-dry/

https://www.youtube.com/embed/pUihe8q03Xc

Large mounting surface

Ideally suited to engineers looking to mount a large object or work piece, this animation showcases how the GV3 carriage plate provides a large mounting surface and is very well suited to carrying physically bigger objects. It is interesting to visually see the physical size of the GV3 carriage plate alongside a ball rail and block. When a large fixture is fitted to the ballrail block, it looks oversized and overhangs, whereas the same size fixture then transferred onto the GV3 carriage plate fits well and looks right. The animation also highlights that the ballrail system requires an additional rail set in parallel, 3 additional blocks and a bespoke top plate to create an equivalent mounting surface to the GV3. Machining is required to prepare the mounting surfaces, as well as the additional cost of the extra components. Under these circumstances, 4 x GV3 bearings are equivalent to 4 x ballrail blocks. Larger GV3 carriages are also available on request for even great flexibility.

https://www.hepcomotion.com/videos/animation-gv3-large-mounting-surface/

https://www.youtube.com/embed/G05gBreYgSc

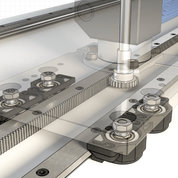

Rack drive

When looking to specify the method of driving a system, favour is often given to a time-saving solution that is quick and easy to assemble. This animation shows how typical ball rail systems require additional components and design work to incorporate a rack drive. Ball rail mounting surfaces require machining before assembly, taking time and adding cost. Conveniently, GV3 rack driven systems can be fitted directly to un-machined surfaces, and as the animation shows, the rack drive and guide are a single assembly; no additional components or design time is needed.

https://www.hepcomotion.com/videos/animation-gv3-rack-drive/

https://www.youtube.com/embed/aFqAt_55JHY

The new animations are available on Hepco’s website at www.hepcomotion.com and are already proving popular with design engineers.