SEW Eurodrive’s Complete Drive Maintenance (CDM) service has helped to increased efficiency and cut maintenance at the Coca Cola plant in Wakefield

SEW Eurodrive’s Complete Drive Maintenance (CDM) service has helped to increased efficiency and cut maintenance at the Coca Cola plant in Wakefield

The Wakefield plant is the largest soft drinks factory in Europe, producing over a million cans of product every day and over 100 million cases of soft drinks a year. The factory has 10 production lines with over 1,500 drive units and Coca Cola was keen to take advantage of the benefits that the new CDM service would deliver.

CDM is an innovative concept that merges an online databank with the management of complete drive maintenance. The databank contains detailed information on every drive component in the factory. Its hierarchical structure is easy to use and intuitive, allowing navigation by factory, building, production line and equipment, depending on the customer’s requirements. At Coca Cola’s factory in Wakefield, clicking on production line 7, for example, would bring up a list of the 325 drives installed on it.

Each drive is given its own CDM tag and code so there’s no need for engineers to go crawling around in cramped spaces with a torch to read the name plate. Selecting any one of the drives takes the user to a page devoted to it.

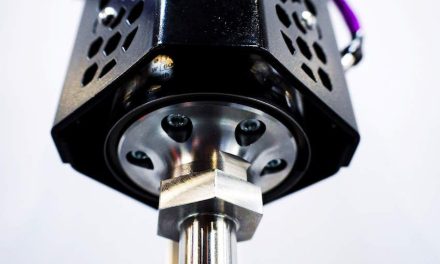

There is a 3D CAD drawing of the unit in the same orientation as it is installed on the production line, a photograph and all the relevant documentation, such as installation and operating instructions. There are also over 40 different fields in which important technical data is recorded, including everything from the unit’s operating voltage to the permitted surrounding temperature.

At this level CDM lists the drive’s service history, it’s current condition and any planned maintenance events that have been scheduled. A really useful feature is the facility to send a message to SEW Eurodrive, about any unit, from within the databank’s product information screen. This feature is simplicity itself. No product codes or references are needed as CDM does all this automatically.

The message could be a request for an onsite inspection of the drive at a specified day and time. SEW Eurodrive’s engineers would then turn up at the appointed time to carry out the required inspection. Everything is recorded and users can review the condition of drives and planned maintenance schedules at any time. Condition monitoring such as vibration analysis and oil age monitoring can also be linked with CDM.

With over 1,500 drives on its 10 production lines at Wakefield Coca Cola were interested in CDM’s ability to target older units that could be replaced with high efficiency motors, helical bevel gearboxes, or the very latest technology, Movigear, to increase efficiency and reduce energy bills.

Over the factory’s twenty year history it has a record of environmental achievements and reducing its carbon footprint. For instance, it sends zero waste to landfill and it has cans supplied from a factory right next door to cut transportation. Following a recent £6m investment the plant is also able to produce its own preforms that are then blown into PET bottles, cutting production costs and delivery miles by over 130,000 a year.

Now, in partnership with SEW Eurodrive, Coca Cola wanted to look at ways of significantly reducing the power consumption of the drives on its 10 production lines. To demonstrate the possible energy savings that could be achieved an older worm gearbox on a conveyor system had its energy consumption monitored. It was then replaced with one of SEW Eurodrive’s highly efficient Movigear units and energy consumption was monitored again.

The results were dramatic. The older worm gearbox was consuming 1.18KW and was costing £1,020 a year to operate. After installing Movigear, on the same application, energy monitoring showed that power consumption had been reduced to 0.31KW with annual operating costs of just £268. That’s an 83% reduction in power consumption and an annual saving of £752 per unit. Across 10 production lines and other equipment in the factory the possible savings are considerable.

Coca Cola’s facilities and utilities manager at Wakefied, Mark White, said: “SEW Eurodrive’s CDM service has enabled us to streamline and simplify our drive maintenance regime and already we’ve seen a marked reduction in maintenance spend due to failures. Our target now is to significantly cut power consumption by replacing the old drive technology on our production lines with modern, energy efficient, units.”

SEW Eurodrive

T: 01924 893855