Ruland pre-designed modular mounting systems are a kit of components that fit together to mount conveyor rails, sensors, screens, cameras, and other industrial components in a variety of applications. These pre-designed systems greatly simplify the design process by giving engineers an easy way to select the group of components that works best for their equipment without having to navigate through five or more pages on a website only to find the components they selected do not fit together. This saves a considerable amount of design time and makes it easier to standardize componentry throughout the machine.

Ruland pre-designed modular mounting systems are a kit of components that fit together to mount conveyor rails, sensors, screens, cameras, and other industrial components in a variety of applications. These pre-designed systems greatly simplify the design process by giving engineers an easy way to select the group of components that works best for their equipment without having to navigate through five or more pages on a website only to find the components they selected do not fit together. This saves a considerable amount of design time and makes it easier to standardize componentry throughout the machine.

Modular mounting system kits are comprised of an assortment of tubes, connectors, mounting components, and accessories that are used for mounting in industrial equipment such as those found in food processing, packaging, printing, and material handling. Ruland pre-designed kits give the user the ability to start with a base design and then customize to the needs of the specific application. Standard options to select are tube length, adding a scale to the tube, and selecting the size of the sensor hole on mounting brackets. Users have the added flexibility of further customization with options such as adjustable levers allowing for rapid adjustments of conveyor height or width without the use of tools and portable magnetic bases for easy portability or removal of components such as screens. Pre-designed systems save designers time by having all of the parts needed to build a complete system on one page, having CAD files for complete systems instead of the individual components, and providing an example of how the different components integrate together should a design dictate the need to build a custom system.

Modular mounting system kits are comprised of an assortment of tubes, connectors, mounting components, and accessories that are used for mounting in industrial equipment such as those found in food processing, packaging, printing, and material handling. Ruland pre-designed kits give the user the ability to start with a base design and then customize to the needs of the specific application. Standard options to select are tube length, adding a scale to the tube, and selecting the size of the sensor hole on mounting brackets. Users have the added flexibility of further customization with options such as adjustable levers allowing for rapid adjustments of conveyor height or width without the use of tools and portable magnetic bases for easy portability or removal of components such as screens. Pre-designed systems save designers time by having all of the parts needed to build a complete system on one page, having CAD files for complete systems instead of the individual components, and providing an example of how the different components integrate together should a design dictate the need to build a custom system.

Pre-designed systems for mounting sensors (such as the one in Image A) are available in three base options: adjustable, 90 degree, and flanged bolt. All three systems have sensor mounting brackets that can accommodate round or tubular sensors with an 8, 12, 18, or 30 mm diameter. Alternatively, users can select a plain bracket with no pre-cut hole to add their own custom sensor hole. Plain brackets can also be used as reflectors in optical sensing applications or to mount screens. The adjustable system features an adjustable connector that allows the user to rotate the sensor 360 degrees along the X or Y axis depending on how the system is installed until the correct position is reached (shown in Image A). The 90 degree system features two tubes fixed at a 90 degree angle. While it contains more components, this design allows users to easily adjust the length and height of the system at a reduced cost when compared to the adjustable system if rotational adjustability is not desired. The flanged bolt base is also a two-way system fixed at 90 degrees, however it only has one tube. The compact and simplified design is ideal for systems that only require the sensor connector to be repositioned in one plane (vertical or horizontal) along the tube.

Pre-designed systems for mounting sensors (such as the one in Image A) are available in three base options: adjustable, 90 degree, and flanged bolt. All three systems have sensor mounting brackets that can accommodate round or tubular sensors with an 8, 12, 18, or 30 mm diameter. Alternatively, users can select a plain bracket with no pre-cut hole to add their own custom sensor hole. Plain brackets can also be used as reflectors in optical sensing applications or to mount screens. The adjustable system features an adjustable connector that allows the user to rotate the sensor 360 degrees along the X or Y axis depending on how the system is installed until the correct position is reached (shown in Image A). The 90 degree system features two tubes fixed at a 90 degree angle. While it contains more components, this design allows users to easily adjust the length and height of the system at a reduced cost when compared to the adjustable system if rotational adjustability is not desired. The flanged bolt base is also a two-way system fixed at 90 degrees, however it only has one tube. The compact and simplified design is ideal for systems that only require the sensor connector to be repositioned in one plane (vertical or horizontal) along the tube.

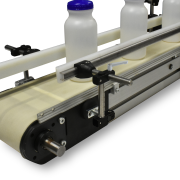

In addition to the sensor mount kits, Ruland has pre-designed systems for mounting guide rails in conveyor applications (shown in image B). They are designed for conical side guide rails with a channel width of 17 mm or 0.67 inch. The two base options for guide rail mounting systems are 90 degree and flanged bolt systems. The systems have the same functional benefits when compared to their use for sensors, however the sensor attachment is replaced by a rail clamp. The use of the same components makes it easy for designers to select the same base system simplifying installation and repeatability throughout the machine. Users can customize the mounting system by adding additional connectors and tubes as needed, such as in double or stacked conveyor rail applications.

In addition to the sensor mount kits, Ruland has pre-designed systems for mounting guide rails in conveyor applications (shown in image B). They are designed for conical side guide rails with a channel width of 17 mm or 0.67 inch. The two base options for guide rail mounting systems are 90 degree and flanged bolt systems. The systems have the same functional benefits when compared to their use for sensors, however the sensor attachment is replaced by a rail clamp. The use of the same components makes it easy for designers to select the same base system simplifying installation and repeatability throughout the machine. Users can customize the mounting system by adding additional connectors and tubes as needed, such as in double or stacked conveyor rail applications.

If a custom system is needed, Ruland has put together a quick tutorial on how to select the various components to ensure they fit together. The tutorial gives detail on each of the individual components that make up the modular mounting systems, how the components fit together, and demonstrates how part numbers are formed. Users can access all components and pre-designed systems from the tutorial page and should have a fundamental understanding of how to build a system after reviewing the tutorial. All modular mounting system components are sourced from JW Winco and stocked in Ruland’s Marlborough, Massachusetts location.

Product link:

https://www.ruland.com/applications/robotic-systems/modular-mounting-systems-robotics.html

UK distributor: Acorn Industrial Services