Based in Worthing, West Sussex, Bowers & Wilkins is an award-winning British company producing high quality hi-fi equipment such as wireless music systems, loudspeakers and portable audio products. Its speakers are often found in top-end studios such as Abbey Road, London and Skywalker Sound, California.

In the past, the graphic design team at Bowers & Wilkins had no way of manipulating 3D CAD data to produce their customer manuals and quick start guides. Their design workflow was restricted by the drawing office’s availability that traditionally had to re-enter the documentation to create 2D formats of each requested 3D drawing. The graphic design team would then use these 2D drawings to create technical assembly manuals for their products, including their wall and ceiling mounted speakers. But if they needed further images, each request would add delays to both teams.

Wanting to speed up access to the engineering data, reduce the dependency of the design team on the drawing office and accelerate products’ time-to-market, the company chose SOLIDWORKS Composer, supplied and supported by NT CADCAM.

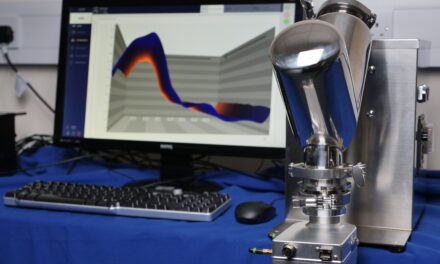

SOLIDWORKS Composer allows users to work directly from 3D engineering CAD data to make high quality illustrations and photorealistic images. Although Bowers & Wilkins use NXD files, graphic co-ordinator Katy Haylor was able to import them as 3D Step files into SOLIDWORKS Composer and work from the entire range of drawings, to get the exact images and angles she wanted.

“Before we started using SOLIDWORKS Composer, time was a big issue,” said graphic co-ordinator Katy Haylor. “I would have to start months before the work was needed, just to get the drawings together for the user guides. Instead of being briefed, then briefing someone else and waiting for them to get back to me to create the artwork – I can now take control of the whole process from start to finish

“As soon as the drawing office has made the step files, I can import them into SOLIDWORKS Composer and have those files in hours rather than wait days. It’s a huge time-saving for me.”

With the 3D files at her fingertips, Haylor said the easy-to-use functionality within SOLIDWORKS Composer means she can manipulate the data exactly how she wants it.

“Our customer instructions can be very involved,” she commented. “They need to be clear and have every step covered, so that anybody can install our speakers themselves. Having access to the technical CAD images helps me visualise the product better and create clearer instructions.

“SOLIDWORKS Composer lets me do things I’ve never been able to do before. We can spin the whole physical speaker around, save different angles or images, do exploded views, highlight screws, change the colour of them, pull them out or hide them away. The manipulation of the 3D data is brilliant. All I have to do next is save the designs as an EPS file and import them into Illustrator to create our manual templates.

“Sometimes if the drawing files aren’t exactly what I wanted or there has been a revision, it would mean going back to the drawing team each time. My hands were tied until someone got back to me and they would also have to halt their workload in order to help me. With SOLIDWORKS Composer I can manage this myself and I am in complete control of the work required. Our workflow is much smoother and we are meeting our deadlines without the late nights and extra stress.”

Beyond graphic content, SOLIDWORKS Composer also creates associative 2D and 3D deliverables that automatically stay up-to-date with the latest design changes. For Katy and her team, in the past incorporating any design changes into a user manual would mean up to a week’s delay. Now any such changes can be revised in a day.

Haylor added: “SOLIDWORKS Composer has completely changed the way we can create our user guides. I am working more efficiently and accurately now and with the added benefits of animations and interactive PDF creation, we are looking to advance our user guides in the future. At the moment we only scratch the surface with what the software can offer us, but so far it has proved invaluable.”