Morgan Advanced Materials, a global manufacturer of high-specification piezo ceramic (PZT) components for defence and commercial sonar applications, has announced a further expansion in its capabilities in this sector.

Morgan Advanced Materials, a global manufacturer of high-specification piezo ceramic (PZT) components for defence and commercial sonar applications, has announced a further expansion in its capabilities in this sector.

The company’s facility at Southampton, UK, is now able to manufacture fully encapsulated hydrophone assemblies.

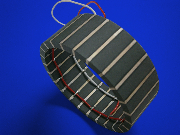

Morgan is an established manufacturer of PZT plates, discs, tubes and (omnidirectional) spherical hydrophones. These are used in both active and passive sonar applications to aid navigation and article / diver detection by providing detailed one-, two- or three-dimensional information on the size, position, distance and movements of objects beneath the surface of the ocean.

The company’s team of application engineers is able to recommend the most appropriate PZT formulation and then fine-tune it to the customer’s specific application requirements. Morgan can supply everything from the base piezo ceramic material, to complete and fully encapsulated hydrophone units. Morgan is able to design and manufacture custom hydrophones and uses the latest underwater facilities to test the performance of hydrophones both at prototype and production stages.

Accuracy and performance can be optimised on (planar) tube hydrophones as a specific example by using the company’s enhanced striping capabilities which ensure the creation of regular, repeatable patterns on the inside surfaces of PZT tubes. These can be pre-stressed before supply for increased performance should that be required.

Dr. Peter Thomas of Morgan Advanced Materials explained: “As an established supplier into the sector, we have a detailed understanding of the performance requirements for hydrophone products. Many of the OEMs and Tier 1 and Tier 2 suppliers are keen to reduce the size of their supply chains, so being able to provide complete hydrophones, combining our materials, design, underwater testing facilities and manufacturing, positions us ideally to maintain and develop our business in this sector. With our knowledge of hydrophones and access to an extensive range of high-performance materials, we are able to design and deliver a cost-effective solution for virtually any application.”