Automotive manufacturers and their supply chain provide a rich collection of automation projects, hence the reliance on the high-performance and reliability of Contrinex sensors. One such example is a manufacturer of switches, which need to ensure the presence of a metal washer.

Applications

The assembly of electrical switches includes a dark metal, wave-shaped washer which ensures a tight mechanical switching action and well–sealed switch assembly. The assembly of the switches is fully-automated and the typical automotive industry quality expectation is that parts are 100% verified.

There is a need therefore to ensure that no switch can be assembled without the washer – The presence of the washer needs to be checked immediately after it is inserted and before the switch assembly continues to the next stage, rejecting the part, or suspending the entire production process.

The switches are small because they are used in vehicles, and therefore the automated assembly line to manufacture them is intricate with lots of moving parts and limited space to accommodate sensors. The uneven surface and dark colour of the wave-shaped washer and the congested area within the assembly line made it difficult for detection with a photoelectric sensor, whilst detecting the metallic washer using an inductive sensor was more flexible.

Solution

The washer is inserted early in the assembly of the switch, at the third station of 15. To guarantee the quality of the assembled switch, the presence of the wave washer is checked before the workpiece passes to the next assembly station.

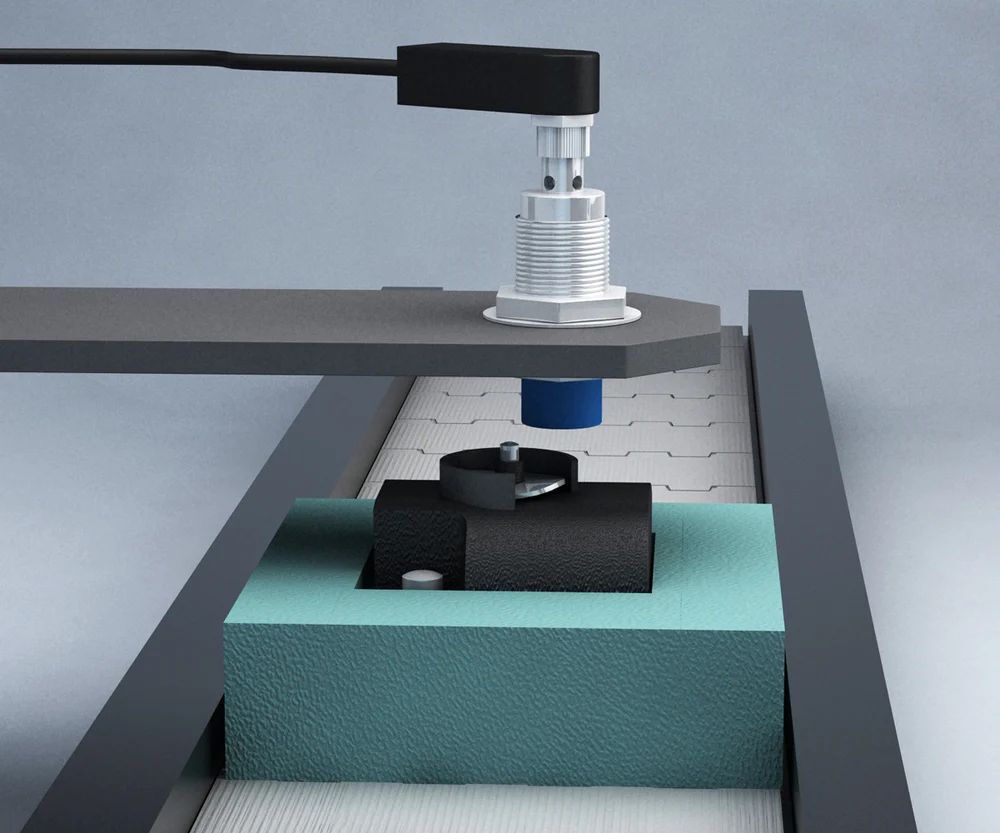

Space within the machinery is very limited, and whilst an inductive offers flexibility with its location, a sensor not larger than M18 was desired. Because of the large number and speed of moving parts within the system, it was considered wise to mount the inductive sensor at a safe distance from the moving workpiece assembly.

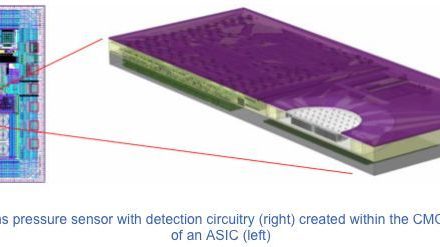

A Contrinex ‘500 Series’ inductive sensor is used because of its long sensing range and its ability to reliably sense the small amount of metal within the wavy washer. The patented Condist® technology provides excellent sensing stability against environmental influences, especially temperature change, which enables in this instance a non-embeddable M18 sensor with a 20mm sensing distance.

The sensor looks down at the workpiece carriers and semi-assembled switches as they pass below on an automatic conveyor line. If the sensor detects a missing washer, the control system activates a solenoid to prevent the workpiece carrier advancing to the next station, whilst an alarm is sounded to alert the operator.

Being able to locate the inductive sensor well away from moving parts protects it from mechanical damage and avoids a frequent cause of downtime. Its excellent reliability ensures end-product quality and eliminates a potential source of customer complaints.

PLUS Automation Ltd is the importer of Contrinex sensors into the UK and Ireland, and can help you #MakeSenseofSensors to improve your Automation and machine performance using Concentration????, Inductive????, Machine Safety????, Photoelectric????, Pressure????️, Ultrasonic???? and RFID???? sensors from Contrinex, ReeR & Satron.

Advantages

Long sensing ranges – Up to 4x standard distance

Fast, accurate high-performance detection

Very affordable & high-performance

Long sensing ranges – 4x standard sensors

Robust & reliable in demanding conditions

Metal housing & Plastic sensing face

Strong EMC protection

-25°C to +70°C – Excellent temperature stability

IO-Link – Ideal for Industry 4 and offering Plug and Play swap-out

Click to download the Product flyer, or Click to download Contrinex’s Product Overview brochure to find out more.